End of Line Solutions

End of Line Automation includes any equipment which would be part of the last 30% of a production line.

- Picking or placing

- Labeling

- Case packing

- Palletizing

- Inspection

- Stretch wrapping

When designing the End of Line Automation solution, there are many things to consider and information to be gathered. Feed rate, size range, type of material, and floor space available are just a few pieces of data that must be understood in order to design the solution. In addition, the industry for which the automation is being designed will have an effect on what types of machines or models of equipment will be selected.

Most often, a variety of conveyors will connect these pieces of equipment and network them together. At this place in the production line the food, paper, beverage, container, building material, personal care, utility product, etc. is already in its individual format or package and the end of line automation does the final work of putting the product into its final package to be palletized. Once the products are palletized, stretch-wrap equipment performs the final process of securing the packages to the pallet for shipment.

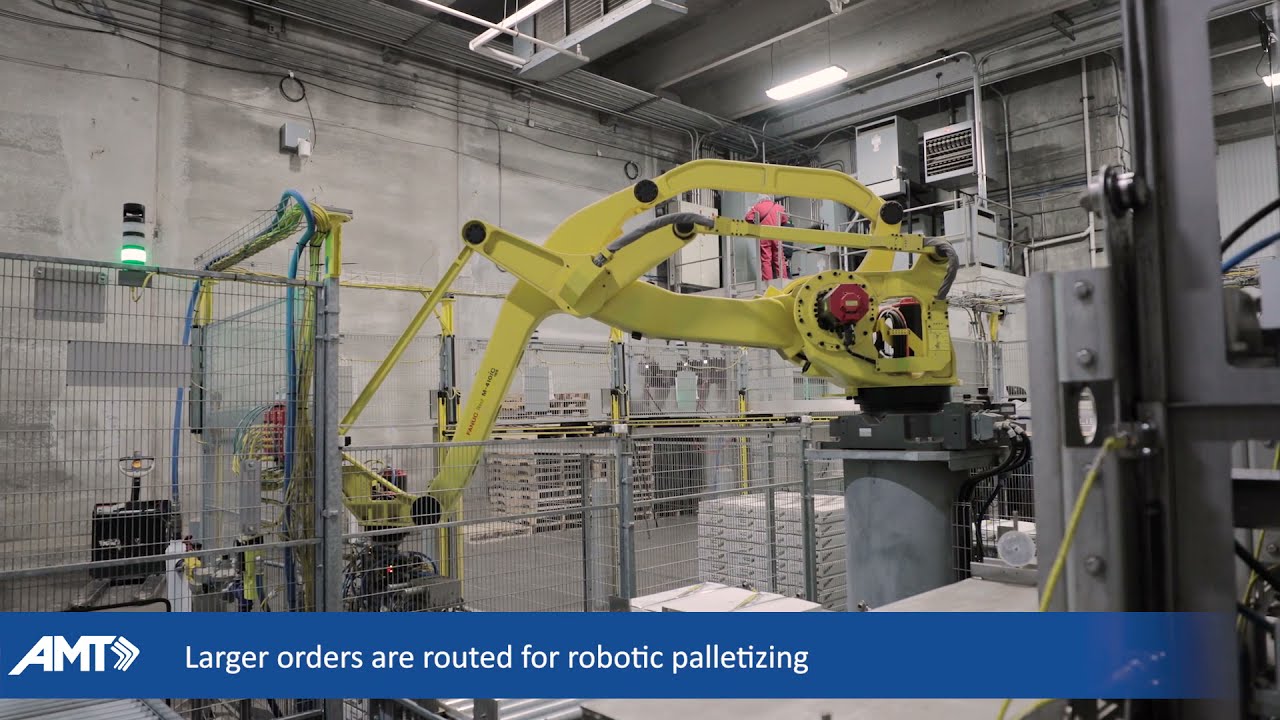

Palletizing

Automated palletizing and depalletizing are critical upstream and end-of-line operations in a wide variety of industries, including warehousing and logistics, food and beverage, aerospace, automotive, and more. Designing and implementing robust robotic material handling solutions is far from one-size-fits-all.

Case Sortation

Sortation is the process of identifying individual items on a conveyor system and diverting them to correct locations using a variety of devices such as pushers, conveyor, or robots. Sorters are applied to different applications depending upon the product type and the required rate.